FlexIC Products

Ultra-low-cost NFC for RFID systems

Our PR1201 and PR1201 Dry Inlay products enable the price point required to add intelligence to everyday objects. Download the product sheets below to discover key features, benefits, applications and technical specifications.

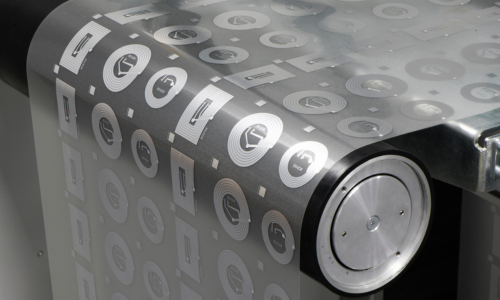

Inlay manufacturers

We work with leading industrial partners to ensure that inlay (tag) manufacturers and converters can use traditional integration tools and production lines to easily integrate FlexICs.

We offer label assemblers and converters our in-house Tag Assembly Line (TAL) resource to develop RFID inlay proofs of concept powered by our FlexIC technology.